Failure mechanism investigation of the adhesively bonded joints using Finite Element and Discrete Element methods

Published in Composite Structures, 2025

Recommended citation: Abylkassimov, A., Kalimuldina, G., Araby, S., & Amanbek, Y. (2025). Failure mechanism investigation of the adhesively bonded joints using Finite Element and Discrete Element methods. Composite Structures, 351, 118574. https://doi.org/10.1016/j.compstruct.2024.118574

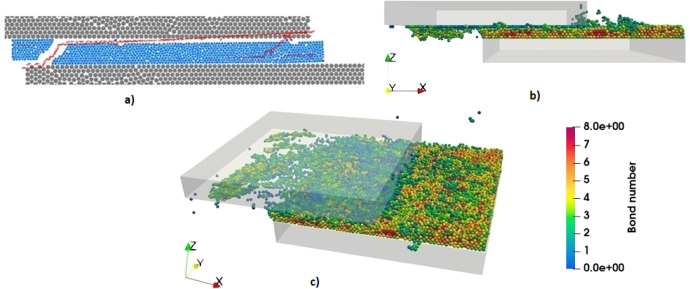

“Structural integrity is commonly defined by strength and durability of structure’s components. Adhesive joints have advantages over welding and bolted joints by less stress concentration, less weight and easier in manufacturing. In this study, numerical modelling analysis is employed to better understand fracture progression and its mechanism in adhesively bonded joints (lap shear joints) subjected to axial loading. Finite element method and discrete element method were used to predict strength and damage propagation of single lap joints. The study utilized Loctite EA 9497 epoxy as adhesive and three different adherends including polyphtalamide–polyphtalamide (PPA–PPA), aluminium–aluminium (AL–AL) and aluminium–polyphtalamide (AL–PPA) in the lap shear joints. The finite element model employed Cohesive Zone Model to examine joint strength, stress distributions along adhesive/adherend interface, and to perform scalar stiffness degradation analysis. The finite element model revealed that the adhesive damage takes place at the interface adjacent to the adherend with lower material stiffness. In addition, validation using load–displacement curves and comparison with experimental data demonstrated good agreement. Subsequently, discrete element model coupled with the Johnson–Kendall–Roberts (JKR) cohesion model was employed to adapted failure progression based on discrete particle interactions. The developed model was verified and compared with experimental results. Using the innovative discrete element method coupled with the JKR cohesion model, the bond number per particle parameter served as a material failure indicator. Analysis from the discrete element approach revealed that failure consistently takes place at the adhesive/adherend interface, irrespective of the adherend type. These study findings provide insights into investigating failure mechanisms in adhesively bonded joints at both macro- and micro-scales. “